Ka945

Ka945 is a New Zealand built steam locomotive, used in the North Island by New Zealand Railways for both express passenger and heavy freight service. The NZR Ka class dominated the NIMT in the later steam years.

- Locomotive running number: Ka945

- Designed by: New Zealand Government Railways

- Built at: NZR Hutt workshops, Lower Hutt

- Date built: 1939

- Builders number: 328/39

- Entered service: July 1939

- Written off: December 1967

- Returned to heritage operation: 1985 to 1995

- Current condition: Undergoing 2nd restoration.

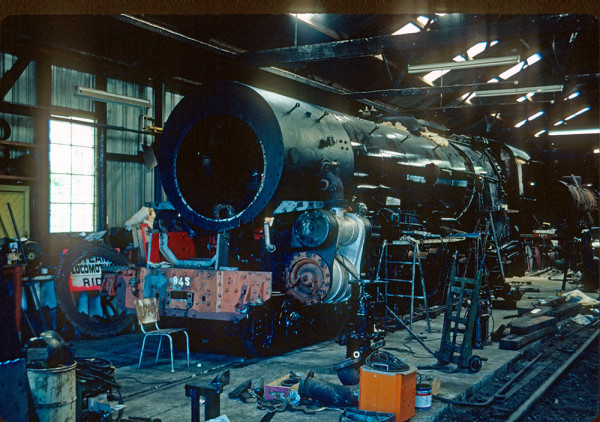

Image: Ka945 Wellington Photo John Bovis

Locomotive details

- Locomotive running number: Ka945

- Designed by: New Zealand Government Railways

- Built at: NZR Hutt workshops, Lower Hutt

- Date built: 1939

- Builders number: 328/39

- Entered service: July 1939

- Written off: December 1967

- Returned to heritage operation: 1985 to 1995

- Current condition: Undergoing 2nd restoration.

Ka945 was the first built of the Ka class.

- Wheel arrgt: 4-8-4

- Driving wheels: 54 inches dia

- Cylinders: 20 inches dia, 26 inches stroke

- Valve gear: Walschaert, 11 inch dia inside admission piston valves

- Boiler pressure: 200 psi

- Total weight in working order: 145 tons

- Overall length: 69ft 8inches

- Tractive effort: 32,740 pounds @ 85% boiler pressure

- Fuel: Oil fired. (Converted from coal in 1947)

- Capacities: Fuel, 1570 gallons. Water, 5000 gallons

History

The NZR Ka class locomotives were an improved version of the K class locomotives first introduced by NZR in 1932. Ka945 was the first built of the Ka class, though not the first in the eventual number series. Among the improvements incorporated in the Ka's were SKF roller bearings in all axleboxes, thicker frames, and a stronger design of the cast steel rear frame under the firebox. Some locos were also subsequently fitted with cast steel (instead of cast iron) cylinders. When designed, the K and Ka locos were arguably the largest conventional locomotive that would fit through the loading gauge on the principal North Island main lines. As originally built, Ka945 was fitted with an ACFI feed water pump and pre-heaters covered by a "streamlined" casing at the front end. This was removed in 1947, the pump and feed heaters replaced with an exhaust steam injector and the locomotive converted to oil firing. Its current appearance is as it was after the 1947 conversion. Unlike some locos of the Ka class, 945 was never fitted with a cross-compound air compressor and is currently running with the dual single pumps at the front end that produce the typical "Ka sound".

Ka945 as built Hutt Shops photo NZR Archives

Ka945 new at Hutt Shops

Ka945 on the Taumarunui turn table 2nd August 1952. Photo JM Creber

Ka945 spent its entire working life allocated to the Taumarunui depot and worked both freight and passenger trains on the North Island Main Trunk, through the "mountain country" between Taumarunui and Taihape. While most of its life was uneventful, in July 1961 it ran in to a large boulder hidden in a slip across the track at Hihitahi, was derailed, and in the process suffered a bent frame.

Ka945 Hihitahi derailment

Hihitahi derailment

The locomotive took part in many rail-fan excursions during the 1960's when steam was being replaced by diesel electric locomotives on the Main Trunk. Its last run in NZR ownership was on 30 September 1967, when it made a return excursion between Taumarunui and National Park traversing the world famous Raurimu Spiral. It was officially written-off in December 1967 but remained at Taumarunui until June 1975 when it was towed to the Steam Incorporated depot (The Engine Shed) at Paekakariki. The locomotive had been purchased by the late Sir Len Southward for display at his proposed vintage car museum at Paraparaumu, and came to The Engine Shed for temporary storage.

While at the Engine Shed the locomotive was partly cosmetically restored. Sir Len subsequently donated the locomotive to Steam Inc. and it was then decided to restore the locomotive to main line working order, even though the likelihood of it ever running on the main line was then exceedingly remote.

By October 1984 the locomotive was in a very stripped down condition for what was expected to be a 5 year overhaul. At that time NZR was planning a steam event to mark the centenary of the start of construction of the last link in the Main Trunk through the "King Country" and Steam Inc. was approached to see if we were interested in having Ka945 take part. Needless to say, we were, but only had six months to restore the locomotive to working order to meet the deadline of Easter 1985.

Ka945 under overhaul in our Paekakariki workshop in early 1985. Photo Reid McNaught

After much hard work and many late nights the locomotive, accompanied by Ja1250 from the Glenbrook Vintage Railway, and the societies combined vintage carriages worked the triumphal Centennial Special steam train from Auckland to Wellington on 13th & 14th April 1985 and returned to Auckland the following week-end. Although officially a "one-off" operation, this train proved to be the start of the return of steam to the main lines in New Zealand. Steam Inc. was subsequently awarded the A & G Price restoration award for this locomotive.

Ka945 leads Ja1250 Porewa April 1985. Photo John Bovis

Ka945 has since run many rail excursions and charters throughout the country and is very popular with rail fans and the general public alike.

945 at Mangaweka working a steam excursion train.

It has, over the years, achieved many places in the rail history books and created many 'firsts'.

To celebrate the locomotive's 50th birthday in June 1989, it hauled a three day excursion from Wellington to Taumarunui and back. At Taumarunui many ex-NZR locomotive crews and maintenance staff had the chance to re-aquaint themselves with an engine that they had known in everyday service many years previously.

Ka945 hauls her 50th birthday train over the new Hapuawhenua Viaduct. Queens Birthday 1989

May 1991 saw Ka945 become the first preserved steam locomotive to haul an NZ Rail scheduled express passenger train. To celebrate the centenary of the completion of the Wellington to Napier route via the Manawatu Gorge, 945 hauled the Bay Express Train from Paekakariki to Napier and back to Wellington.

In February 1992, together with J1234, Ja1250, Da1431 and F163 it hauled passenger trains operated in connection with the 2nd BP Pan Pacific Car Rally at Palmerston North. In September the same year it was the first Ka to run over the Masterton to Woodville line.

In 1993 it first ventured across Cook Strait on the interisland ferry on its way to Invercargill.

KA 945 and the Crunchie train at Maheno near Oamaru, during the epic 3-week non-stop trip for the locomotive. Photo: Glen Anthony.

This was perhaps its greatest claim to fame when it ran, over a three week period, from Invercargill to Whangarei, hauling a promotional train for Cadbury Chocolates. It was in steam for the entire period and ran over 4000km in the process.

1994 saw Ka945 together with Ka942 (owned by the Mainline Steam Trust) re-create the sights and sounds of double-headed steam trains on the Raurimu Spiral and this was repeated the following year. Two Ka's on a heavy train create sights and sounds never to be forgotten and certainly turn the phrase "earth shaking" in to reality.

Ka 945 is an exceedingly well travelled locomotive, having traversed almost the entire New Zealand rail system. The only significant lines it has not run over are from Stillwater junction to Westport in the South Island, and in the North Island, the Rotorua and Taneatua branches, and north of Whangarei.

After 10 years of running, in 1995 the locomotive was taken out of service for a mandatory boiler inspection and overhaul. It was intended at the time that the locomotive should only be out of service for a few years,

however the list of things that needed attention kept growing, combined with a difficult financial period for the society due to it being almost impossible to run excursions on the main line saw the restoration stall. When finances improved, it was decided to concentrate resources on steam loco AB 608 which also was under restoration and Ka945 has sat waiting for its turn for restoration.

Firebox repairs

The project to overhaul 945 commenced again in late 2014. The early focus was on boiler related repairs' especially in the firebox and stays. This was completed by the start of 2017. Attention then turned to the underframe and running gear.

Tender body resting on its side

Fuel bunker removed from tender body.

Recent work in the restoration of our NZR Ka class loco has been focused on the tender and locomotive running gear. By mid 2024 the The tender running gear is almost complete, with the last major job left being the turning of the tyres before refitting the bogies to the frame. A newly refurbished drawgear assembly for the tender has been completed and will be installed once the bogies are in place. The locomotive brake gear has been overhauled and work on the suspension gear is underway, with the main driving wheel compensating beams being completed and fitted to the loco frame. The spring hangers will soon be installed once new bushes have been made and fitted. Other items such as the water gauges, oil burner steam valve manifold have been overhauled and are ready to be fitted when the time comes.

Refurbished compensating beam

Restored water gauge glass

Refurbished oil burner steam manifold.

Refurbished yoke for tender

A fund is kept for the restoration costs of this steam locomotive – any donations towards it are greatly appreciated.

If you are interested in becoming involved with this project and helping see 945 hauling our NZtrain trips again, please come down to the Engine Shed Monday to Saturday and make your interest known to Hamish.

Dropping out driving wheels

Non destructive testing on tender underframe April 2023

Restoration Update May 2025

Amongst the busy programme of our heritage train trips and work on other projects, progress is still being slowly made on the society's Flagship locomotive. Visibly the loco has changed very little if at all, but in the workshop, a number of parts which make her up have been getting their turn for inspection and repairs. Here’s a rundown of what has been completed or worked on over the past year or so.

The Manual and Steam operated Blow-off Cocks

The blow-off cocks overall were found to be in good condition with the odd stud needing replacing here and there. The only major concern that came up from the condition of the spring inside the steam operated blowdown. The springs job is to help control the piston and ensure it moves to the correct position for when the loco is having a boiler blowdown and when it is shut off (which is 99% of the time). It had truly seen better days and many years of service. A new spring has now been put in its place.

The Duplex Pump Governor

This was stripped right down and given a thorough clean. The most significant work required was to attend to the brass piston bore. There were some very faint ridges along the inside of it. It was removed from its housing (with mild difficulty), mounted into the lathe and given a run with some emery cloth. After a while of doing this and the bore was all smoothened out, it was test fitted with the existing piston and ring. Everything was still a nice fit so the need to make new components was thankfully avoided. After an oil up and annealing of the copper gaskets, the governor was assembled again and is now ready for use.

Isolating Valves for the Air Pumps

These valves are open virtually all the time when the engine is operational. But nevertheless, it is essential that they seat without leakage when closed in the event of one of the air pumps failing and needing to be turned off. The valve seats were given a quick machine on our little green Emco lathe and then tested on their seat mates with a touch of engineer's blue. The result was deemed satisfactory, and they were properly reassembled into their housing.

Cylinder Drain Cock Operating Gear

The most recent components to be finished is the cylinder drain cock operating gear. These were stripped and cleaned thoroughly, the piston rings freed up, then the bore relubricated with air oil and reassembled. Work has now started on the drain cocks themselves.

Whistle

Although mostly intact, the whistle was missing two components; a spring and a valve stem. A spare spring was easily sourced, and a brand-new valve stem was machined and lapped into place. The lapping process to a little while, but eventually a perfect seat was made. The whistle was even tested on air, making it the first time since May 1995 that it has made a sound! Even though there was only around 100psi of air pressure to test it with, it was a nice taste test of a sound we will all hear in a few years to come hopefully!

Detroit Lubricator

The five-feed lubricator that sits in the cab of the locomotive has been given a full strip down, clean and overhaul by volunteer Bruce Lawrie. Apart from everything needing a good clean and repacking all the valves, the only major job needed was a replacement valve on one of the feeds. This lubricator provides steam oil to the valves and main pistons as well as the air pumps.

Tender Wheel Sets

Along with this, last year the first two sets of wheels for the tender had their tyres turned and are now part way through bearing inspections. Unfortunately, the axle that has been inspected was found to have worn out bearings which will need replacing with brand new ones. This was not a huge surprise as not all of the bearings for the tender axles were replaced during her overhaul in the early to mid 80s. Some were, however, and this leads onto good news which is that the other two axles which are yet to have their tyres turned have had their bearings inspected and were found to all be in good order to run again. These ones had been replaced during the overhaul.

Driving Wheel Suspension

The suspension for the driving wheels and trailing truck is nearly completed. All the bushings on the linkages and beams have been renewed along with weld building up the coupling ends and bringing them all back to drawing specifications. The compensating beams and new pins to go with them were mainly done by (the now late) Alan Bailey. All of these components have undergone crack testing, which all of them passed! The springs appear to be in decent condition but will be examined closely before attempting to fit them back to the locomotive frame.

Trailing Truck Suspension

The coupling ends on the beams that connect the two trailing truck axle suspension have been weld built up and machined to their correct radii on the mill. The only parts still needing attention are the four springs and the two long beams which connect the trailing truck suspension to the rear driving wheel suspension link arms. The beams simply need new bushings, and the coupling ends measured and repaired as required. The springs, however, will need completely rebuilding as they have splayed in all directions.

Drawbars

The big heavy drawbars that connect the engine and tender together were removed from the back of the cab and have all been cracked tested. While the two smaller guide bars passed no problem, a crack was discovered on the main bar which will need grinding out and welding by a ticketed welder in the future. One of the smaller guide bars did have done wear on it which needed building up with weld. This has been carried out and the small bars have now both been painted and are ready for the day tender and engine unite again.

Dry Pipe Inspection

When steam locos Ab608 and Ja1271 had their dry pipes inspected for their annual boiler inspection’s last year, the opportunity was taken to have a peep inside Ka945’s. An endoscope was sent inside the pipe from the tubeplate end to survey its condition and fortunately nothing of real concern came out of it.

Overview

There is much work ahead, with many major parts awaiting their turn for big work and it will still unfortunately be a few years yet until the Flagship of the society returns to mainline running heading our heritage rail journeys, but every component completed is one step closer to that goal!

Last modified: